Ploughs

Deflector / Ploughs

The standard Flexco Deflector plough has been developed to remove material carrying back on the return side of the belt.

If material is allowed to travel back on the return side it can result in premature wear of pulley lagging, possible build up on tail pulleys can track belts off and lumps travelling around the pulleys can puncture belts or bruise plies.

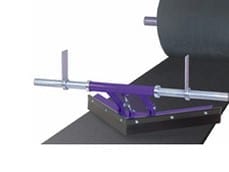

Eliminator® V Plough

The V-Plough “spirals” debris off the return-side belt surface. The V-Plough can also be positioned directly behind the head pulley to dump debris right at the transfer point.

Eliminator® Belt Ploughs feature an exclusive, innovative blade design. The blade’s 20° leading edge “spirals” debris off the return-side belt surface. Compare this to ordinary flat-blade ploughs that often just let debris roll under the blade. Eliminator® Belt Ploughs are also easy to install on virtually any conveyor structure, and come complete with universal mounting hardware.

Self-adjusting unit eliminates the need to readjust to accommodate blade wear.

Stainless steel turnbuckle permits precise adjustment so the plough can be fine-tuned to the belt at installation and eliminate unit vibration.

Can also be positioned directly behind the head pulley to dump debris right at the transfer point.

Rockline® Diagonal Ploughs

This diagonal plough cleans the conveyor belt in front of the tail pulley and discharges the fugitive materials to one predetermined side of the belt for easy cleanup.

Installed on a 45° angle across the belt, the RDP1 Diagonal Plough discharges the fugitive materials to one predetermined side of the belt for easy cleanup. The blade has a 20° angle on the leading edge to “spiral” fugitive materials quickly off the belt. The blade is installed in a fixed position, eliminating any bouncing or vibration problems that may be experienced with floating-style ploughs. Plus, the blade is made of specially formulated UHMW polyurethane for long wear life and less friction and wear on the belt.