Premier Conveyors Rollers

1.1 Premier Conveyors Rollers

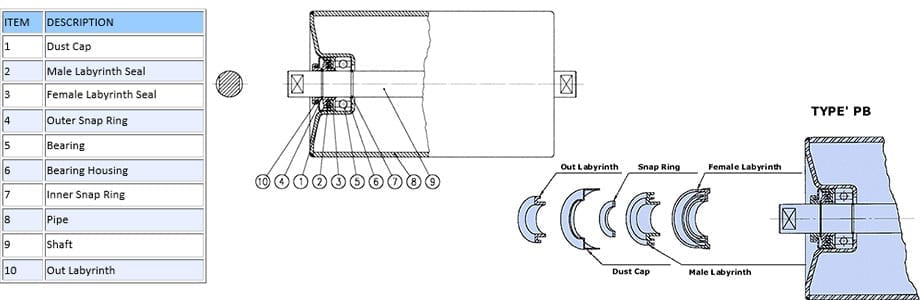

1. With multiple labyrinth sealings. Automatic CO2 synchronized welding, pressed bearing housings and CNC machining, the Premier JW Roller has excellent concentricity.

2. Good dynamic balance (G60 or below), and passed, through the test of dust-proof, water-proof, compression and falling body.

Belt width: from 400mm to 2000m

1.2 Premier Superior Poly Rollers

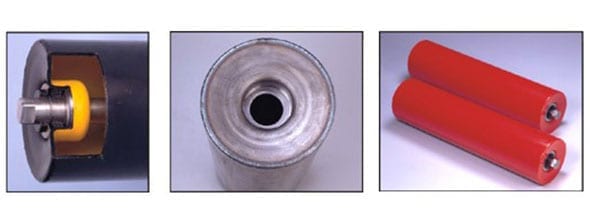

As conveyor rollers play an important roll in the system, correct travel and load support are reliant upon this basic piece of hardware. Successful operators limiting their repair costs recognise the value in using ‘belt friendly’ equipment.

Polymer rollers are gaining wide acceptance, within the bulk processing industries with operators stating they are ‘belt friendly’ compared to the traditional steel shell rollers.

If by chance a unit seizes, it will not produce the same damaging results as it is made from plastic.

If – as is the case in many engineering installations – the rollers are out of view or in an inaccessible place, at least these afford peace of mind because of the minimal abrasive effect on the belt cover should they seize

1. Pipe* (Polymer fabrication)

2. Bearing Housing (Polymer Fabrication)

3. Shaft (SS 400 or stainless)

4. Inner Snap Ring (S65cm)

5. Bearing

Light weight (50% of steel pipe) 6. Female Labyrinth Seal (Nylon)

7. Male Labyrinth Seal (Nylon)

8. Outer Labyrinth Seal (Nylon)

9. Outer Snap Ring (Sup3)

10. Cover (Rubber)